USP/BIOPHORUM Workshop on Continuous Manufacturing of Biologics

In the interest of understanding the current state of continuous manufacturing for biologics and to facilitate the path toward adoption of these promising technologies, the United States Pharmacopeia (USP) and BioPhorum jointly sponsored a hybrid workshop. This article summarizes trends from the workshop and ponders next steps.

Biopharmaceutical continuous manufacturing (BCM) offers many potential advantages over more conventional batch-based manufacturing of biologics.1 Some advantages are apparent based on the nature of a continuous processing, including higher efficiency at lower cost.1 Other advantages may not be as readily evident, including the potential for improved product quality due to reduced and more consistent residence times in the bioreactor, the capacity to adjust product quality process parameters during manufacturing, faster time to release of product (which is especially important for labile products like cellular therapies), and reduced facility costs and environmental impact of the process.1, 2, 3

There are also barriers to the adoption of BCM. Some barriers are technical, such as adapting unit operations that are more suited for batch processes to continuous processing (e.g., viral inactivation or bind and elute chromatography) or correctly scaling each step of a process to allow efficient flow from end to end.4, 5 Other challenges reflect the cautious nature of pharmaceutical manufacturing, like risk aversion and regulatory considerations. Examples of these other challenges include lack of sufficient data to justify hesitancy to change an established manufacturing process or adopt new technology that is not as accepted as existing technologies. 6

The USP/BioPhorum workshop, “Continuous Manufacturing of Biologics: Addressing Barriers to Adoption,” was held 7–8 December 2022 at USP headquarters in Rockville, Maryland.7 The workshop was attended by participants from industry, academia, the US FDA, and others. It consisted of 18 presentations over two days, with panel discussions at the end of each session. The organizing committee for the workshop included:

- Rich Chen, Executive Director, Purification & Viral Safety, Eli Lilly and Company

- Chris Hwang, Chief Technology Officer, Transcenta Therapeutics Inc.

- Maura Kibbey, Director, Biologics Marketing, US Pharmacopeia

- John Kokai-Kun, Director, External Scientific Collaboration, US Pharmacopeia

- Julie Kozaili, Senior Scientist, Asahi Kasei Bioprocess

- Graeme Moody, Program Manager, BioPhorum

- Kristina Pleitt, Senior Manager, Bioproduction R&D Innovation, Thermo Fisher Scientific

- Mark Schofield, Senior R&D Manager, Pall Biotech

- Andrew Zydney, Bayard D. Kunkle Chair and Professor of Chemical Engineering, College of Engineering, Pennsylvania State University

Over the course of the workshop, several trends began to emerge from the presentations and panel discussions. This article summarizes those trends and ponders next steps in the adoption of continuous manufacturing of biologics.

It’s All about the Plumbing

At its most basic level, manufacturing of biologic products involves the movement of various solutions from one vessel to another, through appropriate unit operations that constitute the manufacturing process, in the correct sequence of events.8 For example, this could be the filling of a bioreactor with growth media, the collection of eluate eluted from a capture chromatography step, exchanging the buffer of the final bulk drug substance, or flushing a collection tank with cleaning solution following a manufacturing run.

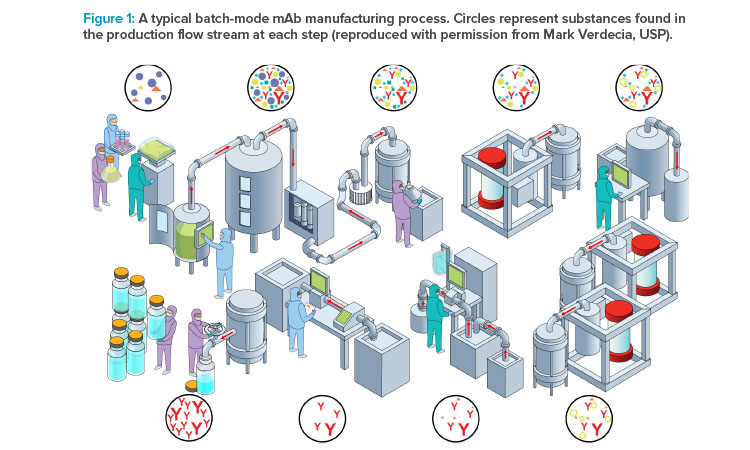

Most bulk biologic drugs begin and end in liquid form, and biologic manufacturing processes are designed to move various liquids into and out of the next receptacle in the process in the correct sequence. Figure 1 illustrates a typical monoclonal antibody production process, showing upstream steps (1–4) and downstream steps (5–12):

- Seed train/cell expansion

- N-1 seed bioreactor

- Production bioreactor

- Harvest

- Capture chromatography (Protein A)

- Low pH viral inactivation

- Polishing chromatography step 1

- Polishing chromatography step 2

- Viral filtration

- Ultrafiltration/diafiltration (buffer exchange)

- Final filtration

- Bulk fill of drug substance: Although this tightly controlled process can be complex in batch manufacturing mode, it is considerably more complicated in a BCM process where, by definition, the product continues to move through the various steps of the process without interruption

Many of the technical challenges associated with designing a BCM process revolve around controlling the continuous flow of the process through each unit operation from beginning to end, especially when the operations may have different optimal flow rates.1 Several operations of a typical monoclonal antibody (mAb) purification process are more conducive to discrete start/stop steps than continuous ones (see Figure 1). These operations include bind and elute chromatography and low pH viral inactivation.

How does a process continue to flow from one step to another when there are starts and stops in the process? One solution that was discussed frequently during the workshop was the use of surge tanks between the various operations. Surge tanks between each step of the BCM process store the outflow from a previous step before it enters the next step. This allows the BCM process to accommodate variables like different flow rates for various operations.

Surge tanks can also be used to divert product streams with suspected deficiencies out of the main flow until a determination can be made as to whether to continue to process the material. Kurt Boenning from Pall Corporation presented a strategy for using surge tanks with three-way valves and automated pump speeds to control a model continuous process. In Pall’s strategy, the surge tanks are mounted on balances so that the volume of material in the tanks automatically control the pump speeds. The dual inlets on the three-way control valves also allow for automated introduction of either product stream or buffer.

Lara Fernandez Cerezo from Merck & Co. also reported that they use surge tanks to control their processes, linking their downstream flow rate with their upstream processing conditions. Merck is currently conducting GMP runs of a BCM process for mAbs so that they can develop a process that can produce sufficient material for phase 1 clinical trials.

Additional challenges lie in the loading and elution of capture chromatography steps. Various strategies using multiple columns are under development, and some strategies have considered the use of up to four identical columns for such a procedure.1

Irina Ramos from AstraZeneca discussed the strategy they are developing with Pak BioSolutions for implementing BCM processes, including their use of multicolumn setups and an integrated control system that can operate four continuous purification stages simultaneously. AstraZeneca uses a two-column configuration, which allows one column to be loaded while the other column is being washed, eluted, and regenerated. A key consideration in this strategy is that the load time for the column needs to be longer than the regeneration time to maximize productivity. They also use column guards and sterile filters to safeguard their systems. Microbial control is further ensured by using a closed system that is extensively tested and qualified before it is run.

Other challenges around the efficient movement of products through the production process were also discussed. Filters are frequently used at various points in a process for activities like sterile filtration, particle removal, and viral clearance, but these filters can become clogged and need to be changed. The flow rate of the process needs to be monitored before and after filters to detect fouling of the filters. One strategy discussed to allow the efficient replacement of filters to prevent a process pause is to use a dual flow path system with two filters where the pressure is monitored and when it reaches a set point, the product stream is automatically diverted to the secondary path next filter while the filter in the first path is changed.

Buffer management is also an essential aspect of any biologic process, but this is particularly true for a BCM process. Charlie Heise from Fujifilm Diosynth discussed their MaruX system, which combines upstream productivity with downstream intensity. Specialized manufacturing skids have been developed that allow 5×-concentrated buffers to be diluted inline at the point of use are included in the system. This has resulted in the footprint for buffers being half of what would be expected. Fujifilm’s BCM facility will be ready for GMP manufacturing in 2024.

Michael Coolbaugh from Sanofi explained that they use a universal skid for all downstream BCM operations. The design goal is for their flexible and modular process to be plug and play with no need for clean-in-place/sterilize-in-place requirements due to the use of single-use equipment that can be replaced rather than cleaned and sterilized between uses.

Tangential flow filtration (TFF) is a technology frequently used in biologic manufacturing processes to exchange buffer or concentrate the product. John Moomaw from Eli Lilly and Company is developing an integrated continuous counter-current TFF system using single-pass membranes. This technology uses a series of dilution and concentration steps with pumps to control the flow. There can be pressure accumulation and inline mixing challenges but including surge tanks can help alleviate this. Eli Lilly is working toward an automated system for use in BCM to develop a non-GMP TFF pilot skid to include in their BCM development work.

Viral Clearance

Biologics are produced by living organisms, often mammalian cell lines, and these cells can carry known and unknown viruses, some of which are endogenous to the cell line. Viruses can also be introduced by operators or come from other raw materials.9 It is a requirement of any purification process that it significantly reduces the risk of viruses being found in the final product.10 Indeed, demonstrating the capability of any process to remove potential viral contamination is an essential part of characterizing the process. This remains true for BCM processes as well, but novel strategies for virus removal and validation of this removal are required.

Scott Lute from the US Food and Drug Administration (FDA) discussed viral safety strategies and how they apply to BCM processes. These include novel strategies to replace the static low pH virus inactivation step used in batch processes (see Figure 1) with technology conducive to continuous flow-through processing. In a conventional batch process, this step generally involves holding the product at a pH of 3.5–4.0 for at least 30 minutes.11

Strategies to adapt this static operation to BCM include alternating dual-tank strategies or flow-through modules that reproduce the low pH hold step in a continuous loop system allowing for continuous flow. AstraZeneca, guided by Pak BioSolutions, uses a size-exclusion chromatography column to achieve the required low pH “hold” for viral inactivation while maintaining a continuous flow. Important parameters like residence time distribution must be characterized and are often investigated by scale-down modeling, where critical parameters include time, pH, temperature, and adequate mixing of the flow stream for the interactions.

Beyond viral inactivation, viral filtration is also an essential step to ensuring the safety of any bioprocess. Small-scale models are often used to study this important step. Ioana Pintescu from Asahi Kasei Bioprocess presented studies that she performed in collaboration with the FDA to validate viral filters under continuous flow filtration. These studies involved spiking known amounts of virus into various solutions and then examining the capacity of the filters to clear those viruses.

Several parameters needed to be considered when planning these studies, including the stability of the virus over the length of the study and the best strategy for introduction and inline mixing of the spiked virus into the test system. These studies demonstrated that the Planova filtration system could remove 6 log PFU/ml of spiked virus. Hironobu Shirataki from Asahi Kasei Medical Co. expanded on the use of their Planova BioEX filters, including the use of multiple filters from 16- to 35-nm pore size.

Another aspect of viral clearance discussed is whether it is necessary to physically sequester material and equipment pre- and post-viral filtration. Fujifilm Diosynth’s and Transcenta’s strategies are to physically segregate potentially virus-positive (prefiltration) from virus-negative (post-filtration) steps in the process and facility, but Sanofi argues that this defeats one of the advantages of converting existing batch processes and facilities to BCM; that is being able to use existing facilities without having to do substantial renovations.

Magnus Schroeder from Just Evotec Biologics presented their advanced integrated, flexible JPOD facility that is conducive to BCM. In their facility design, post-viral filtration operations are segregated from pre-viral filtration. The JPOD facility is a series of modular class B and C rooms in a class D “ballroom.” The modular design makes the facility very flexible, and it is currently scaled for a 1,000-L-scale single-use bioreactor for a BCM process.

A State of Control

In any manufacturing process, control is essential. Control means knowing what is happening and monitoring critical process parameters (CPPs) while making changes as needed. Input and output for the process must be controlled, and a state of control must be maintained throughout the process. Understanding what is occurring at all times and being able to assess the quality of the product are essential to developing a successful process. This allows the process to progress smoothly from one step to the next and to be able to determine when a deviation occurs, which might require diverting and sequestering the product stream until the deviation is resolved.

Not surprisingly, BCM processes can be quite complex to control, requiring the monitoring of numerous parameters throughout the process, from the upstream production steps to the downstream purification steps. The BCM processes discussed during the workshop used various inline analytics for monitoring certain conditions and integrated control modules to maintain control over their process. In the upstream production steps, control and monitoring can include the conditions in the perfusion reactor like temperature, pH, and dissolved oxygen.4 At the same time, in the downstream purification portion, CPPs may be monitored using various technologies.12 Aseptically taking samples from the production stream can be helpful in maintaining control of the process.

Jens Poschet of MilliporeSigma presented their MAST automated aseptic sampling system, which can be integrated into various steps of the BCM process to allow for automated sample acquisition. These samples, taken from both upstream and downstream operations, can then be diverted to various at-line or offline instruments without disrupting the process stream.

Daniel Some from Wyatt Technology presented their ultra-DAWN real-time light-scattering instrument for inline monitoring and real-time release of product. This multiangle light-scattering instrument measures high molecular weight species and particle counts in solutions with changing protein concentrations. The work presented was part of the BioPhorum real-time release workstream.13

Automated process control systems, like Delta V, are often employed to control the various aspects of a continuous process. In Merck’s process, this involves 80 to 100 parameters, and higher titers of product coming out of the bioreactor automatically lead to faster flow rates for the process. The goal is to achieve a steady state in the upstream process before loading the downstream process.

Pall also discussed the titer variations they observe in the perfusion bioreactor, which can be challenging for controlling the downstream purification process. They use remote input/output modules to monitor process parameters like concentration and aggregate removal. This automated control allows for responses like diverting the product stream to a waste tank in response to a failed pH probe, slowing a pump speed in response to a pump flow mismatch, or automatic diversion to an alternative filter unit in response to filter fouling, all without human intervention. Evotec Biologics also reinforced the consensus in the industry that it is automation that enables the success of their modular facility for BCM.

Being able to fully understand a BCM process and how various aspects and variations in the process affect the product outcome can be achieved using a digital twin, which is a digital representation or simulation of the real-world process. Rui Wheaton and Ahsan Munir from National Resilience, Inc. presented their digital twin of an integrated BCM process. This digital twin involves real-time process modeling and data analytics based on a feedback loop of process control. The use of a digital twin allows for analysis of how changes to one part of the process, like an unplanned deviation, affect the other parts of the process. This allows for derisking of many aspects of the process, but, as with any model, it needs to be validated against a real-world process. AstraZeneca also uses data analytics, machine learning, and artificial intelligence to better understand and control their BCM system.

Regulatory Risk

As discussed previously, the advantages of continuous processes to produce biologics are numerous. But, as with any novel technology, there are risks in adopting the technology. Regulatory risk can be broken out into two parts: uncertainty of what needs to be included in the filing, and comparability risks if the BCM technology is being implemented postapproval or late in the development life cycle.

The Emerging Technology Program (ETP) from the FDA is a collaborative program where industry representatives can meet with the team at the FDA to discuss novel technologies prior to filing regulatory submissions. Joel Welch from the FDA presented an overview of the ETP and opportunities for collaborative interactions. Early collaboration on any new technology is key to the success of the program, and the FDA encourages sponsors to reach out to the ETP early in their development process.

Interactions between the sponsor and the FDA may include knowledge transfer and site visits to better understand the technology. These early engagements ensure that the FDA reviewers and industry are ready for future regulatory filings that include these new technologies and can lead to predictability of review. Once a technology graduates from the ETP, it is no longer considered emerging, and it can proceed fully through standard assessment. As of August 2022, 46 continuous manufacturing technologies had been accepted by the FDA into the ETP.

Adoption of BCM

Genzyme was an early adopter of BCM technologies.14 and when Sanofi acquired Genzyme in 2011, the development of BCM continued. Nate Ostberg from Sanofi discussed how a perfusion process can rapidly deliver complex protein drug substances to cut the time to first-in-human trials and cycle times, with as little as 35 weeks between the first transfection of cells and drug substance availability for toxicology studies. Sanofi is developing a platform process that they plan to use for late-stage commercial processes. They use a scale-down model for process development, but one of the advantages of their platform is that pilot and GMP manufacturing can be performed at the same scale.

Sanofi also found that they can often take a cell line and move it from a fed-batch to a perfusion bioreactor with little adaptation required. They have developed continuous capture for two biologics produced by an updated perfusion process. One of the keys to adopting BCM was to demonstrate sufficient comparability to avoid additional clinical trials for licensed products. Sanofi’ssingle-use BCM line, which was smaller and less expensive to build than a fixed facility, is being examined for processes for various molecules, including mAbs and enzyme replacement therapies, in an existing facility.

Merck also plans to use the same scale BCM process for development, clinical, and commercial runs. This has several advantages over fixed facility manufacturing. The formal process characterization execution for all unit operations of a fixed process can last nine months. For example, the ultrafiltration/diafiltration (UF/DF) application for a traditional scale-down experiment requires larger amounts of material per run and can only conduct one experiment at a time, which makes this process-intensive for materials, time, and personnel. This poses a challenge for resources, as many experiments are needed for a typical UF/DF study. This hurdle can be overcome by using high-throughput systems, which enable parallel experimentation requiring only a fraction of the resources.

Rob O’Keefe from Eli Lilly and Company discussed their manufacturing and facility strategies with regards to next-generation bioprocessing. There is concern within Eli Lilly that conventional stainless steel facilities for production of mAbs may be getting too large and BCM may offer an attractive alternative. Eli Lilly compared stainless steel with hybrid and BCM facilities using a 6,000-L disposable bioreactor, including a strategy where two bioreactors feed into one downstream process.

They looked at the economic benefit and cost of goods for the various facilities. Hybrid and continuous facilities in the 1,000 to 5,000 kg per year range are a better option economically than stainless steel facilities. Once production surpasses 5,000 kg per year, however, the cost per gram and the net present costs begin to converge. It is important to focus on the cost of goods for any future gains to break the convergence above 5,000 kg. The projection is that regardless of the optimization effort, there is probably a ceiling of $20–$30 US per gram. The key takeaway is that BCM leads the way in all the metrics.

As previously established,2 water is the single greatest contributor to a biologic product process mass intensity (PMI). Due to the lack of clean-in-place and sterilize-in-place requirements, Eli Lilly demonstrated that BCM processes featuring single-use equipment significantly reduce water use. Because BCM processes can be fully contained, the energy consumption can be reduced by lowering the required room classifications.

In agreement with Eli Lilly’s finding regarding PMI, AstraZeneca reported a 5-fold reduction in PMI for a BCM process compared to a noncontinuous batch process. They also showed that a commercial facility for batch manufacturing can cost $700 million US and take five to six years to build, whereas an equivalent BCM facility using single-use equipment is one-third the size, costs 40% less, and can be built in half the time.

Transcenta Therapeutics Inc. is developing a platform process to support internal drug development as well as contract development and manufacturing organization (CDMO) services. Chris Hwang explained that pricing pressures, especially in developing countries like China, combined with demand uncertainty and the need for rapid response, are driving the development of their single-use hybrid BCM platform and modular facility design. They demonstrated that their “plug and play” continuous perfusion platform can increase cell culture process output by more than 8-fold when compared to same cell lines in fed-batch mode, whereas their “push to high” platform can push productivity even further.

Transcenta reinforced the importance of the cell culture process being under a state of control and integrating with intensified and automated downstream using BCM to debottleneck the upstream production. Rather than end-to-end continuous downstream, they elected to develop and implement hybrid continuous downstream processing, in partnership with MilliporeSigma, given the small footprint of its multiproduct single-use facility and the need to minimize complexity and risks for their GMP implementation in 2023. Overall, they demonstrated by implementing BCM in a small, nimble, and low-cost single-use facility can achieve the output of larger, more costly, and slower to build facilities while driving cost of goods down.

Cost of goods is also driving Parvus Therapeutics, Inc. to explore BCM to produce their Navacims,15 which target cells that cause autoimmune dis-ease and convert T-reg cells into suppressor cells. Joel Bruegger explained how Parvus uses a perfusion process to produce the protein component of their therapy and to recycle unconjugated proteins to increase the efficiency of their nanoparticle formation during conjugation. They get better titers with a perfusion bioreactor and better conjugation efficiency by recycling, which will drive down the cost of goods for their product.

Conclusion

The workshop was well-received, the presentations were enlightening, and the panel discussions following each session were robust. There is momentum within the biologic manufacturing world to move toward BCM. This effort is being driven by many large pharmaceutical companies like Sanofi, Eli Lilly, Merck, and AstraZeneca who attended the workshop. This migration is also being supported by contract organizations and vendors that are innovating in this space.

Companies like Fujifilm Diosynth, Just Evotec Biologics, Transcenta, and National Resilience are all developing processes and technologies to support BCM, and equipment innovators like Pall, AK Bio, Wyatt, and MilliporeSigma are providing novel solutions to overcome some of the technical barriers for adopting BCM. Further supporting this are programs within the FDA, like the ETP and other recently released guidances, including ICH Q13 and FDA Q13,16, 17 to help with regulatory uncertainties.

Although many important barriers related to BCM were discussed during the workshop, some areas and topics were underrepresented. Process analytical technologies,12 including inline and at-line analytics, are supporting technologies for maintaining control of a BCM process and an active area of development at USP. Knowing what is happening in terms of CPPs and critical quality attributes of the product in real time or near real time will be helpful as BCM matures toward commercial use. Wyatt and MilliporeSigma presented their novel offerings in this area. Other development is ongoing in this area and could be featured in future iterations of the workshop.

Another important consideration not fully addressed is the durability of BCM processes and equipment. Many BCM processes under development anticipate the use of single-use equipment in at least some of the process steps,18 but even for processes using durable equipment, the question remains, how long can a process be continuously run and still maintain quality? What is the durability of various single-use components, and where are the critical failure points? For example, Merck is using matrix experiments to determine filter lifetimes to failure. How long can a process be run before microbial contamination becomes a risk? During the workshop, Sanofi reported running their process for two months, whereas Merck ran their process for 24 days, with days 14–24 being under steady state. As BCM matures and moves toward general use, questions regarding the durability of the equipment and processes will likely be an important area of investigation.

The organizing committee anticipates that there will be future iterations of this workshop. As the technology continues to mature, the subject areas of the workshop will expand to include these new areas. USP continues to explore the type of tools and solutions to enable the adoption of BCM, and this work aligns well with existing work at USP on pharmaceutical continuous manufacturing including the opening of a new advanced technology lab in Richmond, Virginia.19