Conventional Aseptic Processing with manual Picture: Fully automated gloveless Robotic Filling operation without Barrier

Fully automated gloveless Robotic Filling

The new EU GMP Annex 1 also contains important information about robotics. For example, in the chapter Principle «Facility, equipment and process should be appropriately designed, qualified and/or validated […] The use of appropriate technologies (e.g. Restricted Access Barriers Systems (RABS), isolators, robotic systems,[…]should be considered to increase the protection of the product.”

The Robotic Session during the 2023 ISPE Aseptic Conference in Bethesda, MA on 6-7 March has been established for several years. One highlight in 2023 is a current case study by PSM GmbH, a CDMO located in Schiffweiler/Germany with their decision for a fully automated robotic aseptic filling line. Thorsten Haefner, Vice President of Business Development, will explain why for a CDMO, responding to their customer requests about manufacturing flexibility has the highest priority and also the current GMP regulatory requirements. For PSM, robotized aseptic filling means more than automated processes, so important requirements from the new EU GMP Annex 1 are considered, such as First Air.

In the new EU GMP Annex 1, the consideration of first air plays an important part. This can be found seven times in the entire document. First air is described in the glossary as follows: “First Air – Refers to filtered air that has not been interrupted prior to contacting exposed product and product contact surfaces with the potential to add contamination to the air prior to reaching the critical zone.”

Section 4.4 also states "Grade A: The critical zone for high-risk operations (e.g. aseptic processing line, filling zone, stopper bowl, open primary packaging or for making aseptic connections under the protection of first air)."

Particular attention should be paid here, especially when using robotic solutions. Robots take over the manual interventions previously performed by an operator. It is important to ensure that the robot does not make any movements interrupt the first air or generate turbulence to interfere with the unidirectional airflow. The same applies to the use of robots, for example, to open the closure of a ready-to-use RTU where there are pre-sterilized vials or syringes packed or to transport the sterile containers through the filling and closing process.

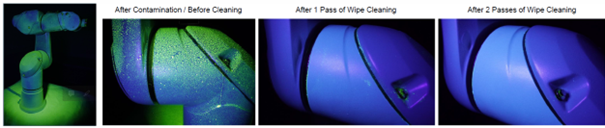

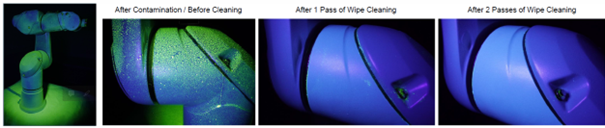

Another important point is the cleaning of the entire system as well as the built-in robots. In the new EU GMP Annex 1, Section 5.4 is described as " The cleaning process should be validated to be able to: ……….. Minimize chemical, microbial and particulate contamination of the product during the process and prior to disinfection”. This also means particles that have built up on the robot during manufacture or particles from the manufactured product. In both cases, cleaning is important from a GMP point of view, whereby cleaning with regard to adhesions of the manufactured pharmaceutical product involves the risk of cross-contamination of the next produced product if the Robot is not appropriately cleaned. The built-in robot systems must therefore also be able to be validated cleaned, and their seals must be designed to ensure cleaning of them, too. If applicable, the cleaning should also be in compliance with operator and environment safety if highly potent products are manufactured.

Wipe Cleaning of a Robot and the results after 1 Pass or 2 Pass of Wipe Cleaning

Another focus of the project presentation is paperless production. All data is collected and released electronically in order to meet the requirements of Pharma 4.0.

While writing this blog post, I needed a short break, which I used to go to the Assembling Hall and see what Isolator projects are currently being set up and what an unplanned big surprise I met Christa Myers from CRB there. We have known each other for many years and have accompanied many joint projects. We are both on the annual ISPE Aseptic Conference program committee and have been friends since we first met. We both agree that the next aseptic conference in 2023 will be full of interesting topics. Plenty of time for discussion, networking, and interactive workshops in smaller groups.

In that sense, back at my workplace and now have a few important pieces of information for the 2023 ISPE Aseptic Conference. In addition to actively participating in the conference, don't forget to bring fun, a big smile, and a good mood with you. Talk to your colleagues about the Aseptic Conference because it's more productive to come together to participate in all sessions than alone. Ask a lot of questions because it's your future that we're shaping with the Conference and the knowledge provided. Take back home more than you brought with you, especially the new knowledge you gained and hopefully new friends from our ISPE Aseptic family. In any case, now it`s time to wish you HAPPY Holidays with your family.

As always yours Richard Denk

Learn More & Register